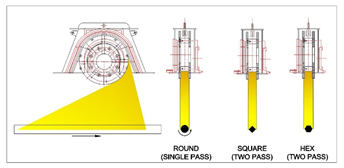

Single Blast wheel machines ( Inline ) – bars

Components held in rubber belt cavity formed between barrel head plates. The rotation of the barrel head plate causes the components to tumble. The high velocity abrasive from the top clean the components from all sides. Applications – forging / castings and Al die casting.

| TECHNICAL SPECIFICATIONS | |||||||

| Particulars / Model | GLINT SPBB2 | GLINT SPBB2 | GLINT SPBB4 | ||||

| Bar range | 16 mm to 52 mm | 18 mm to 80 mm | 40 mm to 120 mm | ||||

| Total connected load | 19.5 HP | 25.5 HP | 28.8 HP /46 HP | ||||

| Blast wheel | 15” - 1 | 15” – 1 | 15” -1 / 2 | ||||

| Auto loader and knock out | Motorised (Optional ) – 2HP | Motorised (Optional ) – 2HP | Motorised (Optional ) – 4HP | ||||

| PLC control | Optional | Optional | Optional | ||||

| Production rate | For 16mm –500 Kg/hr For 52 mm -2300 Kg/hr | For 25mm –1200 Kg/hr For 80 mm - 4100 Kg/hr | For 40mm –1800 Kg/hr For 120 mm - 4800 Kg/hr | ||||